Sudokwon Landfill: The art of putting food scarps to good use

By Habib Toumi

INCHEON: Standing on the upper part of Landfill One and its 64 million tons of waste buried underneath, Public Relations Specialist Hong Seung-hee, impeccably dressed and hair blowing in the slight breeze, pointed to a garbage truck, the last of the 350 that empty their load of the 5,500 tons of domestic waste, food waste and residual waste in construction sites at Landfill Three.

The site was the third landfill in the ambitious project executed by the Sudokwon Landfill Management Corporation, an agency under the Ministry of Environment.

in 1992, when the first land filling began, about 40,000 tons were brought in daily; however, the implementation of the state-led waste reduction policy, brought the amount down to 15,000 tons in 2014 and to 5,500 tons in 2023.

The new landfilling project has turned the Republic of Korea into a worldclass example on how to use breakthrough ideas and to leverage technology to deal efficiently with waste and benefit from it.

For instance, the Integrated Waste Receiving System identifies the types, origins, and amount of incoming waste in real time. The systemic receiving inspection scheme prevents illegal waste from coming to the landfill site.

The world dumps a stunning 2.12 billion tons of waste every year, and Korean household and industrial sites, as a result of the country’s rapid urbanization and economic growth, had contributed to the global increase of waste volume.

In fact, according to according to the Food and Agricultural Organization (FAO), each South Korean on average generated more than 130 kilograms of food waste each year, while the per capita food waste in Europe and North America is 95 to 115 kgs a year.

However, South Korea has achieved a global hero status and set an example to be emulated after it has in the last three decades adopted a radical waste management policy that ensured that the mountains of wasted food are recycled, and that open dumping was transformed into safe disposal, recycling and waste-to-energy conversion.

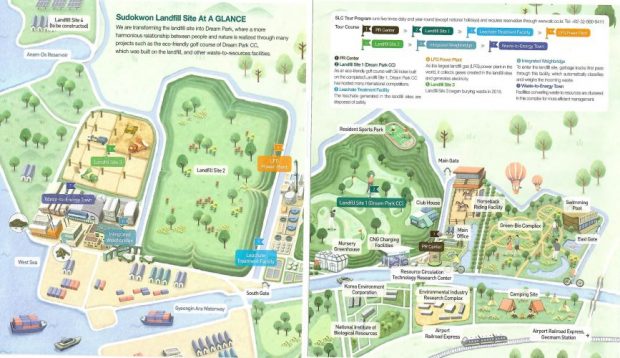

Since 1992, waste from Seoul, Gyeonggi and Incheon Metropolitan area has been taken to Sudokwon Landfill where it was buried.

The Sudokwon Landfill, the world’s largest, was built on reclaimed land that filled the sea to form a total area of 16 million square meters, or the size of 2,300 soccer fields, Hong Seung-hee said.

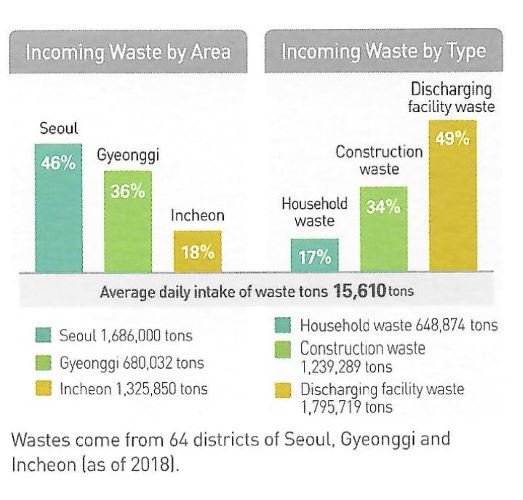

In 2018, discharging facility waste represented 49% of the incoming waste, construction waste 34%, and household waste 17%.

Seoul then led with 46% of the total waste, Gyeonggi followed with 36% and Incheon had 18%.

Howeverm in 2023, the amount of waste brought in by the local government was 491,000 tons (28%) from Seoul, 187,000 tons (11%) from Incheon and 615,000 tons (35%) from Gyeong-gi province.

Landfill sites one and two have been completed while reclamation is progressing steadily at site three.

Landfill One was used from February 1992 to October 2000. In October 2013, its upper part was opened as Dream Park CC, an ecological space and leisure park on reclaimed land featuring a public golf course used by 160,000 people annually.

In 2014, the course, selected as the best eco-friendly golf course in Korea, hosted the Asian Games Golf competition and the US Women’s Open Championship.

All profits generated by the course are reinvested in the region following discussions with the local residents.

As the buried waste decays, the site whose height has subsided by about 7.2 meters, is sinking at an average of 2.4 centimeters per year.

Even though landfilling ended in 2000 at the site, it still generates landfill gas and leachate as trash rots.

The three landfill sites combined generate a daily average of 4,900 tons of leachate that are transported to the leachate treatment plant through pipes installed on the floor.

The treatment process includes three stages – the leachate collection and homogenization, the biological treatment that decomposes organic matter using microorganisms, and the chemical treatment of the remaining non-degradable organic substances.

Through the process, it is treated and exported at a level ranging from one fourth to one tenth, or less, of the emission standard.

Landfill Two, spread over an area of 3.7 million square meters, was used from October 2000 until September 2018.

As the reclamation method at Sudokwon Landfill is bottom-up, five-meter-long layers, each made by covering 4.5 meters of trash with 50 centimeters of soil, are stacked eight times to reach a height of 40 meters.

However, after the reclamation is completed, the uneven settlement requires a stabilization period before future use plans are determined and carried out.

The landfill features 699 above the ground pipes to collect the gas that will be transported to the 50 MW power generation plant that produces electricity using landfill gas. The plant can generate 50MW per hour.

The power plant, completed in December 2006 and operating full scale commercially since March 2007, has a daily generation of 675 MWh, generating $70,000 in electricity sales revenue per day and cumulative sales of $424,215,000.

The landfill gas power generation has, over the past 10 years, reduced carbon emissions equivalent to the amount emitted by 3.4 million passenger cars in a single year.

The corporation has also secured 8.82 million tons of carbon emission rights (CER) and the 5.1 million tons it sold by 2021 have generated a $50,684,000 profit.

In its bid to minimize the impact of landfilling waste, the corporation has opted not to use the entire Landfill Two and to divide it into 24 blocks measuring 300 meters horizontally and vertically. The landfilling work is thus carried out only in three areas at a time – Two normal landfills and one detailed inspection.

Landfill Three is made up of eight blocks measuring 400 by 200 meters.

However, as the amount brought in has decreased, work is being carried out in one block only, unlike the multi-block approach adopted in Landfill sites one and two.

Waste is treated hygienically through unloading, spreading, compacting and covering the waste.

The soil is covered daily with a thickness of 20 centimeters on top of the waste brought in on that day. This ensures that there is no exposed waste at all when the daily work is completed.

Landfill Three has reached level 4-5, with landfill progress rate at about 60%.

Action by Sudokwon is not confined to sanitary landfill work, but also extends to carrying out projects to turn waste into resources.

“We are saving 4 billion won ($3,057,000) per year by turning sewage sludge that was discarded into the sea into organic dry fuel and supplying it to thermal power plants and others and using biogas generated from food wastewater as fuel for sewage sludge resource recovery facilities.”

The corporation has a nursery greenhouse that produces plants to be used in turning the Sudokwon Landfill into a Dream Park. The greenhouse uses gas generated from food wastewater as a heat source. It hosts spring and fall flower festivals for citizens by displaying plants grown here.

“The nursery greenhouse is employing 1,700 local residents annually.”

Within its wild flower complex, Sudokwon Landfill has a two-kilometer cherry tree road and a wild flower complex over 630,000 square meters. The site was a place where briquette ash was stored in the past.

The complex features a swimming poll and a dog park that was used by 240,000 people in 2023.

The corporation has signed concluded 20 Memoranda of understanding (MoU) with 12 countries, including Mongolia, Vietnam, the Philippines, Colombia, Nepal, Cambodia, Russia, Hong Kong, Ecuador, Sudan, and Angola.

Eleven of the MoUs were concluded between local governments and public institutions, while nine were between local private companies.

One more case is currently under review with the Vietnamese government.

The Sudokwon Landfill Management Corporation said that it employs 318 full-time people, but the figure reaches 1,000 when each service provider and local residents are included.

Nearby, the gas generated at the Seoul Metropolitan area waste (around 9,000 ton per day) landfill sites is used by Ecobio Holdings’ 50 MW power plant, the world’s largest, to produce electricity.

The company is involved in production of electricity and gas businesses and is engaged in the development, operation, and sale of renewable energy business in South Korea.

The company is also involved in production of biosulfur activities. In addition, the company engages in organic waste gasification business, as well as invests in technology related activities; and constructs, operates, and manages power plants.

The construction of the 50MW power plant lasted 33 months, from March 2004 to December 2006. Operations started in March 2007 to remove sulfur oxides (Sox) of air pollution substance in advance and supply as eco-friendly fuel.

In October 2014, the company constructed a sulfur oxide pre-treatment facility. The power plant relies on steam turbine (50 MW). The sulfur oxide pre-treatment facilities use biological methods with microorganisms (H2S concentration is 20,000ppm – 200 ppm).

The eco-friendly power plant generates electrical power about 400,000,000 kWh/year using biogas LFG. It can be supplied to 110,000 homes (based on 330kWh/month per home) or 180,000 homes (based on 200kWh / month per home).

The plant, also the world’s first and largest eco-friendly Bio-Sulfur producer, includes the removal of hydrogen sulphide (H2S) in the mixed gas stream and produced by microbal metabolism.

The outcome can be used as a concentrated fishery fertilizer/ feed. Raw material for household goods, raw material for cosmetics and medicine, Ecobio Holdings Vice President Young Min Kim said as he welcomed a group of Asia-based journalists.

Using LFG as the energy resource, Ecobio is adding value to the economy while minimizing the impact on the environment in the nearby surroundings and preventing global warming.

The company, formerly known as Eco Energy Holdings Co., Ltd., changed its name to EcoBio Holdings Co., Ltd. in April 2016.

It is headquartered in Seoul.